Congress is “moving slowly” on the issue of power supply, the Commerce Secretary said

When Trade Minister Gina Raimondo appeared on Yahoo Finance in January, she said one of her key problems was ongoing: a law spending over $ 50 billion on semiconductor production. “There is an urgency,” she said at the time, adding that “the foundations of this law have broad bipartisan support.”

But more than 3 months later – and without much progress on the Capitol Hill issue – her patience evaporated in a subsequent appearance.

“I think they’re moving too slowly,” she told lawmakers this week in an interview with Yahoo Finance Live. “The country needs it, the military needs it, and I think it’s time for them to muffle the gas and do what’s right for America.”

The bill she was debating is currently being negotiated in Congress. The Senate first passed the U.S. Innovation and Competition Act (USICA) nearly a year ago, and the House followed a similar law in February.

There are title provisions that are the same in both laws, including billions for the semiconductor industry and money for scientific research. But key differences remain over other issues, including philosophical divisions on trade and U.S.-China relations.

Trade Secretary Gina Raimondo before a congressional hearing in April. (Thassos Katopodis / Getty Images)

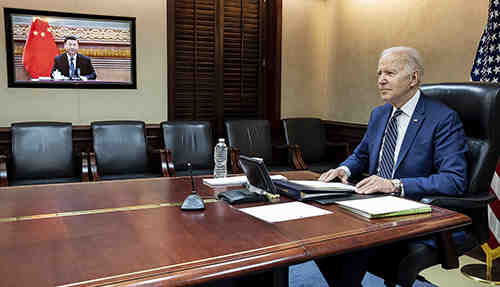

For months, President Biden also urged Congress to finalize the bill, saying the bill would help ease current bottlenecks and inflation – such as in the auto industry – and strengthen America’s position vis-à-vis competitors like China.

‘At the top of every CEO’s list’

“The trade department is taking the lead in this,” Raimondo said of the ongoing negotiations. “Every day we talk to companies. I would say that this is at the top of the list of every CEO I talk to, especially those in defense who I could add. ”

Defense contractors like Lockheed Martin (LMT) are particularly concerned about the shortage because many weapons racing in production for delivery to Ukraine depend on semiconductors.

On Tuesday, President Biden traveled to Alabama to highlight some of the work being done to keep Ukraine armed with things like Javelin anti-tank missiles.

During an appearance at Lockheed Martin’s plant in Alabama, he noted that “each of the Javelins you produce includes more than 200 semiconductors.”

The United States sent over 5,500 weapons systems from the shoulders, which were designed to stop tanks and which were allegedly effective against the Russian fleet. Lockheed Martin officials told Yahoo Finance that more than half of the chips in each system are used in the Javelin launch system, while the rest is inside the rocket itself.

“It’s not just about inflation, it’s primarily about our national security,” Raimondo said.

Members of the Armed Forces of Ukraine fire an anti-tank missile Javelin during exercises in Ukraine, in this picture published on February 18, 2022 (Press Service of the Ukrainian Joint Forces Operation / Handout via REUTERS)

Chip shortage is ‘life-threatening for Americans’

The role of the U.S. in semiconductor manufacturing has fallen from nearly 40% in 1990 to 12% today, according to a recent report by the Semiconductor Industry Association. The situation is even worse with the most advanced logic semiconductors in the world, of which 100% were produced abroad in 2019.

Raimondo also mentioned a recent conversation with CEOs in the field of medical devices. She reports that these companies also cannot get chips and in some cases pay 500 times per chip as much as they paid a year ago.

She recently hosted White House executives to highlight the role of semiconductors in the U.S. economy, from home appliances to smartphones to power generation.

In the case of medical devices, Raimondo says there is no time to waste. “It’s life-threatening for Americans, and that’s why I don’t have a lot of patience for Congress, because lives are at stake and we have a solution ahead of them.”

Ben Werschkul is a writer and producer for Yahoo Finance in Washington, DC.

Read the latest financial and business news from Yahoo Finance

Follow Yahoo Finance on Twitter, Facebook, Instagram, Flipboard, LinkedIn, YouTube and Reddit.

Some governments are also increasing their investment in semiconductor technology to reduce the impact of global supply chain disruptions. However, it is unlikely that the current chip shortage will be addressed in the near future, in part due to the complexity of the semiconductor manufacturing process.

Are semiconductors coming back?

The global shortage of chips will recede in 2022 – but there are two bright spots, says JPMorgan. The global shortage of chips could recede by 2022 – but the situation could improve from the middle of the year as more stock becomes available, says Gokul Hariharan of JPMorgan.

How long will the semiconductor shortage last? Experts do not expect the supply situation to calm down by mid-2022 at the earliest, if not by 2023.

Is the semiconductor shortage getting better?

Unless there is a sharp drop in demand, the shortage of chips will not end soon, analysts say. Most industry executives warn that the shortage is unlikely to diminish before the second half of 2022, with some products still lagging behind due to chip shortages in 2023.

Is the chip shortage getting any better?

The lack of chips remains a significant factor for the industry going into 2022. For the full year, Ford expects the chip situation to improve and plans to deliver 10% to 15% more cars than 2021. In the US, it would manage to reach approximately 2.1 million or 2.2 million vehicles.

Is semiconductor shortage improving?

Fitch Ratings-Chicago-07. February 2022: Global semiconductor supply shortages could begin to narrow in 2X22, despite pockets of near-record low inventories across the supply chain, due to increased capacity and potential to reduce demand from currently high levels, Fitch estimates.

Why is there a semiconductor shortage 2021?

Lack of chips – less supply, more demand Gathering problems has led to a shortage of semiconductors. In addition to long-standing problems within the industry, such as insufficient capacity in semiconductor factories, the COVID-19 pandemic has introduced unprecedented challenges.

Why is there a chip shortage in 2022?

The war in Ukraine, the blockade of COVID-19 in China and the earthquake in China will have a short-term impact in the first quarter of 2022, but “may have long-term consequences for severely limited supply chain throughout the year,” analyst Chris Rolland said.

Will chip shortage improve 2022?

Fitch Ratings-Chicago-07. February 2022: Global semiconductor supply shortages could begin to narrow in 2X22, despite pockets of near-record low inventories across the supply chain, due to increased capacity and potential to reduce demand from currently high levels, Fitch estimates.

What is causing the shortage of semiconductors?

Gathering problems has led to a shortage of semiconductors. In addition to long-standing problems within the industry, such as insufficient capacity in semiconductor factories, the COVID-19 pandemic has introduced unprecedented challenges. For example, carmakers cut chip orders in early 2020 as vehicle sales plummeted.

Which country produces the most semiconductors 2021?

According to a Wall Street Journal report, Taiwan is the country that currently produces the largest number of chips worldwide. Taiwan Semiconductor Manufacturing Company (TSMC) holds 53% of the global semiconductor foundry market (2nd quarter 2021).

Who is the largest producer of semiconductors?

The largest semiconductor manufacturing company in the U.S., TSMC, short for Taiwan Semiconductor Manufacturing Company, is by far the world’s largest chip maker. It is also the sixth most valuable company in the world with a market capitalization of over $ 600 billion and supplies chips such as Apple, Intel and Nvidia.

What country makes the most semiconductor chips?

In 2021, semiconductor sales reached a record $ 555.9 billion, an increase of 26.2 percent, and sales in China reached $ 192.5 billion, according to the Semiconductor Industry Association.

Is there still a shortage of semiconductors?

The automotive industry was severely hampered by the shortage of semiconductor chips in 2021, and the consequences were further exacerbated by the pandemic. Several manufacturers are still feeling the pressure, and many believe supply problems will continue to affect the industry until 2022.

Is the semiconductor shortage over? Unless there is a sharp drop in demand, the shortage of chips will not end soon, analysts say. Most industry executives warn that the shortage is unlikely to diminish before the second half of 2022, with some products still lagging behind due to chip shortages in 2023.

Is semiconductor shortage improving?

Fitch Ratings-Chicago-07. February 2022: Global semiconductor supply shortages could begin to narrow in 2X22, despite pockets of near-record low inventories across the supply chain, due to increased capacity and potential to reduce demand from currently high levels, Fitch estimates.

Will chip shortage get better in 2022?

The U.S. Department of Commerce has released a report on the semiconductor supply chain that predicts a global chip shortage will last until the last part of 2022, and probably even 2023, meaning photographers are likely to continue to see a shortage of new cameras for many months to come. .

Is semiconductor supply improved?

Semiconductor companies have increased bandwidth, which will contribute to the expected revenue growth of about 9% in 2021 – compared to approximately 5% recorded in 2019, the last year before the pandemic.

Why is there a shortage in semiconductors?

Initially, the shortage was partly due to higher demand for more advanced chips from the consumer electronics and computer industry through Covid-19. In context, global semiconductor sales fell between 2018 and 2019, but by 2020 sales had grown by 6.5%.

Why is the semiconductor shortage getting worse?

Global semiconductor shortages exacerbated by the coronavirus pandemic and supply chain problems show no signs of improvement as industries around the world have had to stop production while waiting for processors.

What is causing the shortage of semiconductors?

Gathering problems has led to a shortage of semiconductors. In addition to long-standing problems within the industry, such as insufficient capacity in semiconductor factories, the COVID-19 pandemic has introduced unprecedented challenges. For example, carmakers cut chip orders in early 2020 as vehicle sales plummeted.

Will the semiconductor shortage get worse?

Global semiconductor shortages exacerbated by the coronavirus pandemic and supply chain problems show no signs of improvement as industries around the world have had to stop production while waiting for processors.

What happens to the lack of semiconductors? The lack of semiconductor chips was exacerbated by the pandemic. Manufacturers are increasing the production of chips – but the shortcoming will not be solved immediately. Despite current problems, the industry remains highly profitable.

What is the chip shortage problem?

The lack of semiconductors will directly affect consumers. This disrupted the global supply chain and limited electronics production. Chip prices are rising, and as a result, the prices of electronic devices are rising. Companies like Apple and Samsung started stockpiling early.

Which cars don’t need chips?

Is the chip shortage affecting all cars?

There is a shortage of microchips around the world at the moment, and this is affecting almost every industry. The automotive sector is no exception, and car production has gained a huge hit around the world due to the lack of microchips.

How long will chip shortage affect cars?

How long will the chip shortage last? No one can predict exactly how quickly the shortage of semiconductor chips will end. But experts seem to agree that the shortage will last until the second half of 2022. Some car directors estimate that production will not return to the level before the pandemic by 2023.

Are all car manufacturers affected by the chip shortage?

Other manufacturers, including Jaguar Land Rover, Mazda, Nissan, Subaru and Toyota, said that although the lack of a chip affects overall vehicle production, they do not limit features as a way to solve the problem.

What vehicles are affected by the microchip shortage?

When it comes to the models most affected by the shortage, the Ford F-Series pickup is first on the list with 109,710 units less planned for production. 98,584 fewer Jeep Cherokees are planned, while 81,833 fewer Chevrolets Equinox are in the pipeline.

Is there still a microchip shortage for new cars?

For car buyers, the news means that shortages will continue during 2022. They could be reduced compared to last year’s extremes. GM said last week that it had seen better consistency in semiconductor procurement during the first quarter than last year as a whole.

How long will the chip shortage for new cars last?

On January 25, 2022, the US Department of Commerce reported that the average stock of semiconductor chips fell to only 5 days of stock, compared to 40 days before the pandemic. Large semiconductor companies do not expect the situation to disappear in the next 6 months.

Are new cars affected by chip shortage?

All new cars are made with a multitude of built-in microchips to control everything from window motors to navigation systems, and the car manufacturing industry has been hit hard because the lack of chips has caused a slowdown in production. For consumers who are hungry for new cars, that means fewer are available.

Why is there still a chip shortage for cars?

While the lack of a chip can be attributed to several factors, the COVID-19 pandemic is the primary cause. At the start of the pandemic, carmakers closed factories and temporarily halted vehicle production. Meanwhile, blockades and virtual work and schools have caused an increase in demand for other electronics.

What will happen to 2021 vehicles without chips?

The world will lose 11.3 million units of production in 2021 due to a lack of chips, according to AutoForecast Solutions. Go past any almost empty dealer to see what this looks like on earth. The impact could be another 7 million units in 2022 and 1.6 million in 2023, predicts IHS.

Why are there no chips for new vehicles?

Why is there a chip shortage? Carmakers have canceled semiconductor orders in the early stages of the coronavirus pandemic. As the economy began to improve, gaining access to these materials proved extremely difficult because foreign chip suppliers had already awarded them to consumer electronics.

Are there still cars waiting for chips?

When will stock shortages improve? Automotive analysts at IHS Markit are cautiously optimistic that 2021 was the biggest stock crisis, but chip shortages and other supply chain disruptions are expected to continue – to a lesser extent – until 2023.

Comments are closed.