Comparison of Silicon Carbide with Other Semiconductor Materials

Understanding Silicon Carbide (SiC) as a Semiconductor Material

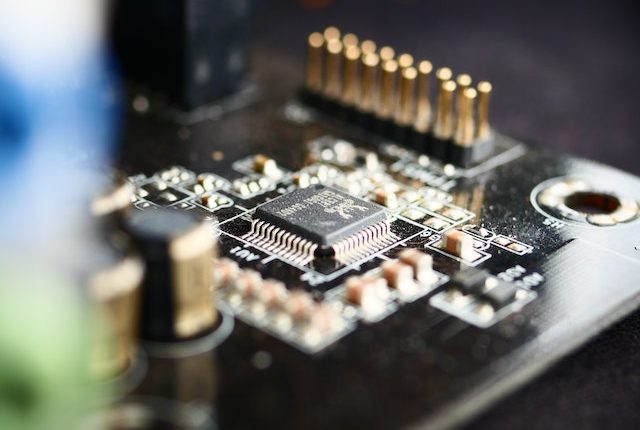

In a realm distinct from conventional semiconductors like silicon, Silicon Carbide (SiC) has burst onto the scene as an intriguingly promising semiconductor material. An astounding compound of bonded carbon and silicon atoms arranged in a crystalline lattice structure, SiC is unique in its composition and properties.

Its display of exceptional thermal conductivity permits devices constructed with it to function at elevated temperatures sans the risk of overheating. Furthermore, SiC semiconductors’ wide bandgap allows them to perform efficiently even under severe voltage conditions, adding another feather to their cap.

The potential for applications embedding Silicon Carbide-based elements extends across diverse sectors but finds particular resonance within power electronics and automotive industries. These domains demand devices capable of managing higher voltages and frequencies than traditional silicon-based counterparts can handle—making SiC’s characteristics immensely beneficial. Power electronic deployments such as Electric Vehicles (EVs), which necessitate components that endure extreme operating environments while maintaining peak performance attest this fact. Moreover, MOSFETs developed using SiC instead of typical materials like Gallium Nitride (GaN) have demonstrated enhanced efficiency levels—a notable achievement indeed!

However, despite the multitude of benefits associated with employing Silicon Carbide as a semiconductor material, there exist certain perplexities that need resolution before industry-wide adoption can be realized. The main point of contention lies in manufacturing complexities leading occasionally to lower yield rates for SiC devices compared to their silicon peers—a situation presently being tackled by ongoing global research endeavours according to recent news reports on advancements in semiconductor technology development processes.

The Unique Properties of SiC Semiconductors

Riddled with a set of uncommon properties, Silicon Carbide (SiC) semiconductors stand as an unrivaled choice for high-power applications. A striking feature of SiC is its power density, which exceedingly outperforms conventional semiconductor materials such as silicon and gallium arsenide (GaAs). This allows SiC to tolerate higher voltages and offer unmatched power capabilities—a boon especially to electric vehicles (EVs), where the traction inverter module demands resilient components capable of managing high-voltage operations.

In the realm of conduction performance under elevated temperatures, SiC asserts its superiority once more. Unlike other semiconductors like GaAs and Gallium Nitride (GaN), it remains unscathed even when operating at soaring temperatures. Electronic devices crafted from SiC wafers can brave harsh conditions typically found in industrial settings or beneath the bonnet of an electric vehicle because they maintain effective functionality under extreme temperature scenarios. Hence, these devices are perfectly suited for circuits intended for high-power applications.

Yet another remarkable trait that distinguishes Silicon Carbide resides in its thermal conductivity—an aspect where it surpasses other semiconductor substances significantly. An enhanced thermal conductivity signifies better heat dissipation—an indispensable factor while handling high-powered electronic apparatus wherein overheating could trigger failure or damage. Moreover, this advantage paves the way for designing compact yet potent modules by amalgamating Insulated Gate Bipolar Transistors (IGBTs) and diodes onto a single chip—thereby boosting efficiency while mitigating size and weight restrictions; vital factors particularly within RF electronics industry where space is frequently scarce.

Silicon Carbide-Based Devices and Their Advantages

The distinctive traits of SiC semiconductors have rendered them a compelling choice for power apparatuses. SiC’s energy differential, in comparison to silicon, is notably vast – a feature that permits these devices to function at extremely high voltages and temperatures compared to their conventional silicon-based contemporaries. The crystalline lattice of silicon carbide offers superior thermal conductivity, proficiently dissipating heat and curbing energy wastage during operation.

Silicon Carbide (SiC), as an alternative semiconductor material, has been employed in manufacturing diverse device types; from diodes to MOSFETs on Silicon Carbide substrate instead of the typical silicon wafers. These SiC-centric devices portray lower on-resistance relative to their silicon counterparts which subsequently drives improved efficiency within high-power applications. Moreover, leveraging SiC substrates results in fewer lattice discordance issues when contrasted with GaN materials – thereby enriching device performance and reliability.

Peering into future development trajectories within the realm of power electronics industry unveils manufacturers’ desire for expanding their SiC product repertoire owing its superiority over traditional elements like Silicon (Si). The adoption pace of Silicon Carbide suggests not merely another transient trend but signifies substantial technological progression destined to transform our approach towards power management across various application spectrum- from electric vehicles to industrial machinery right up till renewable energy systems! Although this swift expansion brings forth certain challenges specifically pertaining cost-efficient production procedures or achieving enhanced yields yet these hurdles are expectedly conquerable given time hence why many envisage SIC as emblematic next-gen technology within this field!

In-depth Analysis: Silicon Carbide and Silicon in Power Electronics

The emergence of Silicon Carbide (SiC) as a revolutionary semiconductor material within the power electronics realm is attributed to its unique performance and electrical properties. Its crystalline structure, superior in thermal and electronic aspects compared to conventional silicon-based IGBTs, positions it as an optimal selection for high-power applications.

A striking feature – SiC’s broader energy gap between conduction band and valence band – results in a pronounced breakdown electric field. This intriguing characteristic enables devices to function at elevated operating frequencies without succumbing to failure.

Moreover, MOSFET components made from SiC demonstrate impressive thermal conductivity that bolsters their resilience against extreme temperature fluctuations whilst preserving optimum performance levels. Such features find particular favor with power modules used in DC power systems where designs often necessitate stable operation amidst variable environmental conditions. Furthermore, the saturated electron drift velocity of SiC facilitates expedited charging time – an attribute exploited by electric vehicles like Tesla Model 3.

Despite Silicon Carbide’s immense potential across various industries due to its superiority over other materials such as gallium arsenide or even silicon itself, researchers are ceaselessly delving into recent advancements aiming towards further enhancement of its capabilities. Efforts are currently focused on improving upon the naturally high resistivity displayed by SiC via molecular level modifications within its crystalline structure.

As we persistently navigate this promising terrain providing insightful analysis regarding potential uses and benefits through our website; one thing stands out about Silicon Carbide: A unique fusion of characteristics renders it primed for substantial growth within the power electronics sector moving forward.

Comments are closed.