Understanding Silicon Carbide as a Semiconductor in Power Electronics

A fascinating shift is unfolding within the sphere of power electronics, with Silicon Carbide (SiC) emerging as a material that could potentially revolutionise this domain. In times past, silicon-based semiconductors have held sway over this sector, but SiC has begun to challenge this dominion with its unique attributes that make it particularly desirable for power devices – namely its wide bandgap, high thermal conductivity and superior performance under high temperatures.

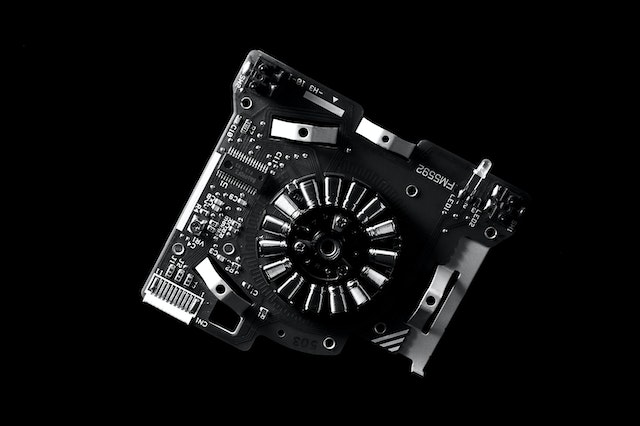

Peering into the heart of SiC’s advantage over other materials reveals an intricate crystal structure. When utilized in power devices, these structures confer significant benefits. The method by which these SiC crystals are cultivated involves subjecting silicon and carbon atoms to conditions of intense heat yet low pressure – akin to sublimation on steroids. This gruelling process yields a dense crystalline formation virtually devoid of defects – an outcome that bolsters the overall efficiency of the semiconductor device at hand.

Moreover, when pitted against their silicon counterparts, these SIC devices brandish an impressive ability to manage higher voltage levels while keeping energy losses during operation at bay.

Of late, whispers about leveraging Silicon Carbide in power electronics have swelled into tangible interest due to its potential for reshaping various industries such as automotive technology or telecommunications including renewable energy sectors among others. Furthermore, SiC-powered devices promise alluring enhancements like diminished switching losses and lessened conduction resistance – both contributing towards a more efficient system without forsaking reliability or longevity.

In essence then – Silicon carbide (SiC), through providing solutions tailored specifically for demanding industry requirements continues shaping tomorrow’s landscape within the realm of power electronics.

Exploring the Role of SiC in Power Devices

Silicon carbide (SiC), a crystalline compound of great intrigue, has carved its niche in the complex world of power electronics. Notably, SiC crystals bask in their wide bandgap – a perplexing characteristic that confers them an ability to efficiently operate under high-temperature and high-voltage conditions where silicon-based devices would falter. This broad bandgap permits SiC semiconductors to handle higher voltages and function at escalated temperatures beyond 200°C. Furthermore, these robust SiC crystals are known for their resilience against potent electric fields without succumbing to breakdowns.

In the realm of power supplies, particularly those found in electric vehicles (EVs), converters and inverters shape the energy flow with crucial precision. The intriguing idea of harnessing an SiC-based power module instead of traditional silicon components promises improved efficiency due to superior thermal management capabilities coupled with reduced size. MOSFETs made from this unique material offer enhanced performance even under elevated temperatures compared to standard transistors – making them perfectly suited for EV applications.

Beyond EV power supplies, there lies a whole spectrum bursting with potential uses for Silicon Carbide’s impressive traits. High-power systems such as industrial motor drives or renewable energy installations often demand diodes capable of enduring extreme conditions; these needs can be met by using bipolar junction transistors or diodes crafted from impurity-free Sic wafer over conventional materials.

The Rise of SiC Power Devices in Modern Electronics

In the realm of power electronics, a game-changer has emerged in recent years – Silicon Carbide (SiC). This innovative material is a compound of silicon and carbon, yet its attributes starkly contrast with traditional silicon. High-power applications have witnessed an exceptional difference as SiC-based devices exhibit heightened performance compared to their regular silicon counterparts. The key lies within their capacity to function at elevated temperatures without compromising efficiency.

Explorations into the intricate world of SiC technology have given rise to numerous electronic components such as Schottky barrier diodes, Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs), and Insulated-Gate Bipolar Transistors (IGBTs) that employ SiC in their construction. A complex process involving polytype transformations brings about these components from SiC powder, eventually resulting in Sic fibers. Not confined merely to electricity transmission, these advanced materials find utility even in Electric Vehicles (EVs) due to their remarkable resistance against high temperatures.

The advantageous nature of incorporating Silicon Carbide into power systems is beyond impressive. Utilizing this cutting-edge material allows for substantial enhancements over conventional silicon-based devices regarding energy efficiency and thermal management – elements critical for many power electronics applications. From an industrial standpoint, it translates into electronic devices composed of SIC delivering more electricity while being more energy-efficient than those made from standard materials like gallium arsenide or ordinary silicon.

This ongoing trajectory towards adopting SIC-oriented power electronics signifies how this groundbreaking material persistently molds the future vista of contemporary technology.

Advantages of Using SiC in Power Electronics

Silicon Carbide (SiC), a material of extensive bandgap, boasts superior traits over its silicon counterpart, making it an ideal candidate for power electronics applications. Its high power density gives SiC a distinctive edge, resulting in devices that are compact and petite compared to traditional silicon-based ones. Besides, the expansive bandgap allows these SiC devices to function at elevated temperatures without any deterioration in performance.

The cultivation method employed for pure SiC wafers involves techniques like sublimation or chemical vapor deposition methods ensuring top-notch results. Compared to other semiconductors such as gallium nitride (GaN), this process yields unparalleled performance characteristics. High-voltage GaN devices often find themselves trailing behind their SiC counterparts due to intrinsic limitations tied with GaN’s constricted bandgap.

Furthermore, Industry 4.0 has seen escalating demand for medium- and high-voltage applications including industrial motor drives where employing Sic offers significant benefits. Power MOSFETs crafted from Sic manage greater current densities while keeping resistance levels low during operation – a trait much coveted in contemporary electronic systems. It is worth mentioning that prior to being acknowledged as an effective semiconductor material, Sic was principally used as an abrasive owing to its diamond-like hardness level; presently though through refined fabrication processes we can harness the potential of growing sic crystals beyond abrasion into spheres where conventional Silicon falls short.

Comments are closed.